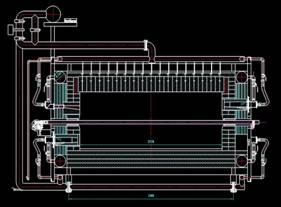

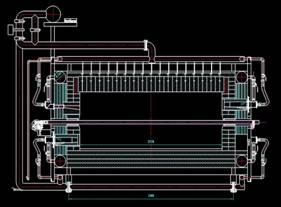

The structure of this roller kiln is box structure. According to functions of each part, the kiln can be divided to 7 parts: steel structure part, refractory material structure part, pipeline system, firing system, gas or oil pipe, transmission system, temperature controlling system, and safety system. Roof tile making machine. |

|

â™?Refractory and Heat Preservation Materials of the Kiln

The selection of the refractory and heat preservation materials is according to the temperature requirement of different kiln sections. In order to ensure the life of the kiln, higher level than temperature requirement of the materials is to be selected. To reduce the energy consumption, it’s better to select materials with low heat conduction coefficient. Roof tile making machine. |

|

â™?/strong> Refractory and Heat Preservation Materials of the Kiln

After filtering impurities by the system and through leveling off the voltage, the gas/oil enters the burner by auto controlled valve. Many burners are interlaced collocated on the body of the kiln, and make the heat source of the kiln even and easy to adjust. 4-8 burners are set at every part of the firing parts. These burners are interlaced collocated to the kiln. 6-8 branch burners are set to be one group, adopting intelligent instrument and upper machine to auto control.Roof tile making machine.Roof tile making machine.

Firing system considers the characteristics of the fuel. Safety shutting off valve, voltage leveling off valve and electromagnetism valve are set at the main pipe. When gas pressure oversteps the setting or power cut, the valve cut the supply of the gas automatically.Roof tile making machine.

Each control loop can control 6 or 8 burners. Set the roller as the border, the upper and lower burner controls separately to adjust the up and low difference of temperature. The section of the kiln chamber sets upper fire resisting plate and low fire resisting wall. Space between the fire resisting plate and the roller can be adjusted according to demand. The function is to adjust the burning curve according to technical demand, and can improve the temperature equality of the section.Roof tile making machine. |

|

â™?/strong> Transmission System

The whole kiln adopts 45°bevel wheel driving method. Every 3 kiln sections forms a driving group, each with a decelerating motor, dragging by motors and with transducer control for tile’s distance control. The whole kiln consists of 3 groups of transducers for controlling the distance of the tiles. The driving system has the functions as follows: switch of supply power and generating power, group driving swing function, supply power driving function without transducers. It has the advantages of steady, reliable driving, low faults, long life and wide range of speed adjustment. Roof tile making machine. |

|

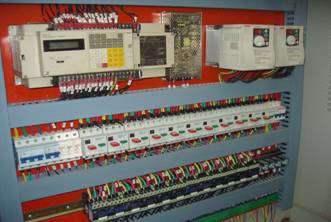

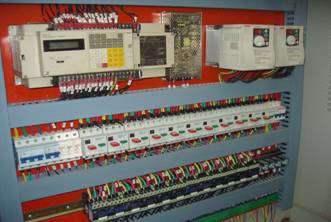

â™?/strong> Control System

The control system of the kiln consists of 5 systems: driving system, fan system, temperature control system, oil or gas/oil control system, warning and safety system, power cut switch system and intelligence management supervising system.Roof tile making machine.

Fan Control System: The fan control systems are divided into to types, manual control and automatic control. |

|

â™?/strong> Manual control:

The control power source is sent to the field from central control room through manual medium relay. Roof tile making machine. |

|

â™?/strong> Automatic Control:

It is a sequence starting procedure for automatic control condition. When starting, the smoking drawing fan starts and after delay for some time, the fast cooling fan can start, and delay for another time, the heat drawing fan can start. After starting, the switch on the operation panel or choosing switch for the field fan can be used. The opening degree of the wind gate shall be paid attention to when starting Automatic fan starting. The automatic starting fan system is locked when generating electricity. Roof tile making machine. |

|

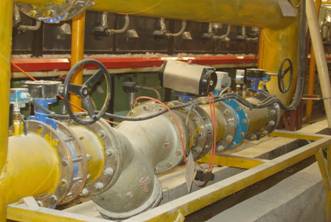

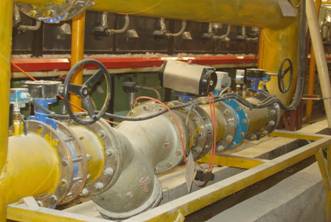

â™?/strong> Gas System

This picture is the gas system of the gas roller kiln. The calorific value of the artificial occurred furnace gas is low and the flux is large. Water draining pipe and tar draining pipe need to be set and the pipe design shall satisfy the energy consumption requirement of the products sufficiently. Roof tile making machine. |

|

â™?/strong> Fast Cooling System

This picture shows the fast cooling system of the kiln; the drawing fan inputs the wind equally into the kiln through refractory steel pipe, adopting frequency conversion to control the temperature of the fast cooling section. The high precision can satisfy the requirement of the technics and adjustment of thermal system. Roof tile making machine. |

|

â™?/strong> Biscuits Storing System

This picture shows the large biscuits storing system, biscuits square of 100-250m2 can be stored. This equipment ensures the uninterrupted production of the kiln. Roof tile making machine. |

|